October 17, 2025

iFLYTEK Showcases Ten Cutting-Edge Tech Innovations at 2025 World Manufacturing Convention, Unveiling Antelope Industrial Large Model 3.0

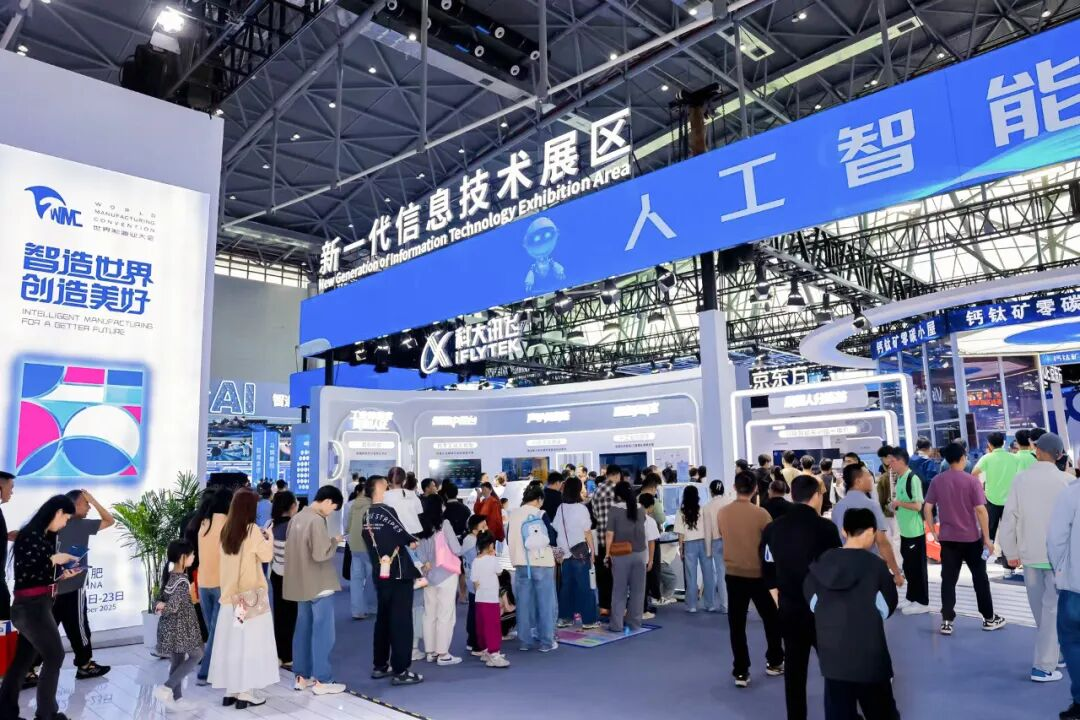

From September 20 to 23, 2025, the World Manufacturing Convention took place at the Hefei Binhu International Convention and Exhibition Center. iFLYTEK presented a suite of ten advanced AI technologies — ranging from AI Industrial Endoscope that can detect critical aircraft cracks as fine as 0.01 millimeters, to AI Acoustic Imager fitted with 132 “super ears”; from iFLYTEK Multilingual Transparent AI Display, which provides translation support in 37 languages, to All-in-One Embodied AI Appliance for Data Collection, Training, and Deployment that empowers robots to “learn and flexibly apply new skills.” Together, these innovations illustrated how artificial intelligence is permeating deep into the finest capillaries of modern manufacturing.

This weekend, the iFLYTEK exhibition area in Comprehensive Hall 2 was buzzing with excitement, with long queues forming at the check-in and lucky draw zone. By around 3:00 PM on September 20, more than 50 visitors were eagerly waiting in line. A student surnamed Xu from Anhui Water Conservancy Technical College exclaimed, “It feels so cutting-edge! I had no idea iFLYTEK’s business covered so many fields.” At the “Ear Age Test” zone, children eagerly pulled their parents into line to experience the fun of determining their “real age” through a hearing test. The vibrant atmosphere served as a vivid reflection of how AI is becoming part of everyday life while driving the transformation and upgrading of the manufacturing industry.

"AI Clairvoyance" + "AI Super Hearing": Leaving No Hidden Risks in Manufacturing

Inside Hall 2, iFLYTEK's AI Industrial Endoscope acts as a "clairvoyant eye" that peers deep into machinery. In a matter of seconds, it captures high-definition images from inside an aircraft engine and generates a corresponding 3D model, enabling precise detection of critical cracks as fine as 0.01 millimeters.

The AI Acoustic Imager, equipped with 132 microphones, can "hear" toxic gas leaks from up to 200 meters away and visually pinpoint them on a display screen.

Standing beside the endoscope was the AI Acoustic Imager — a device equipped with 132 ultra-sensitive microphones that serve as "industrial super ears." At a thin-plate plant of a leading steel group in northern China, this system identified over 20 negative-pressure gas leaks in just one round of inspection. Its 132 highly sensitive "industrial ears" instantly converted abnormal sound signals into visualizations on a screen, enabling operators to see the leak. At Beijing Shougang Co., Ltd., this technology slashed inspection time from five hours (using the traditional soap-bubble method) to just 30 minutes, boosting efficiency tenfold.

From "Master's Intuition" to "AI-Standardized Output"

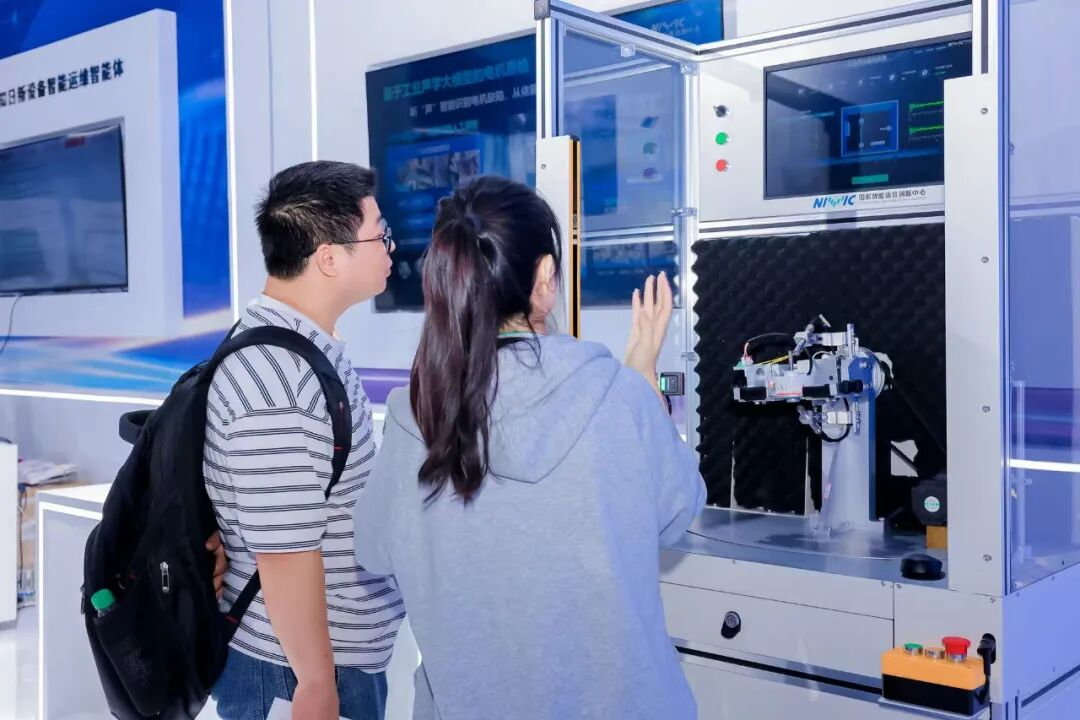

The motor manufacturing workshop is witnessing a paradigm shift—from reliance on a master craftsman's intuition to data-driven quality control. Traditionally, inspection depended on seasoned technicians who would "listen" to each motor to diagnose issues—an approach marked by subjectivity, inefficiency, and an error rate as high as 5%. Now, the Motor Acoustic Quality Inspection System, showcased in the lobby of Hall 2, leverages core technologies like the industrial acoustic model independently developed by the National Intelligent Voice Innovation Center. This allows AI to “detect faults through sound,” reducing the misdetection rate to below 1% and cutting inspection costs by 50%.

The Motor Acoustic Quality Inspection System can test motors of all sizes, from the large ones that power high-speed trains to the small ones inside electric toothbrushes. It ensures that only products meeting quality standards leave the factory, serving as a reliable guardian for what is often called the "heart of industry."

This solution has not only established unified quality standards but also operates around the clock. As a result, it has become virtually impossible for a faulty motor to pass through the production line — effectively bringing the era of "defective motors slipping through" to an end.

The "Go-Global Genius" That Speaks 37 Languages

As manufacturing companies go global, language barriers often emerge as a major hurdle. iFLYTEK Multilingual AI Transparent Display is redefining opportunities for cross-language collaboration in the industry. At the exhibition, the device drew crowds of visitors eager to try its real-time translation feature. When a Turkish exhibitor spoke into the transparent screen, fluent Chinese translations instantly appeared on the opposite side, prompting amazed reactions from the audience: “It’s so accurate!” The device supports real-time recognition and translation in 37 languages and maintains over 95% accuracy even in noisy environments. Already, iFLYTEK Multilingual AI Transparent Display has been widely adopted across nine sectors—including banking, airports, and government services—in more than 100 application scenarios.

iFLYTEK Multilingual AI Transparent Display enables seamless understanding between speakers of different languages, significantly improving the quality and efficiency of cross-lingual communication.

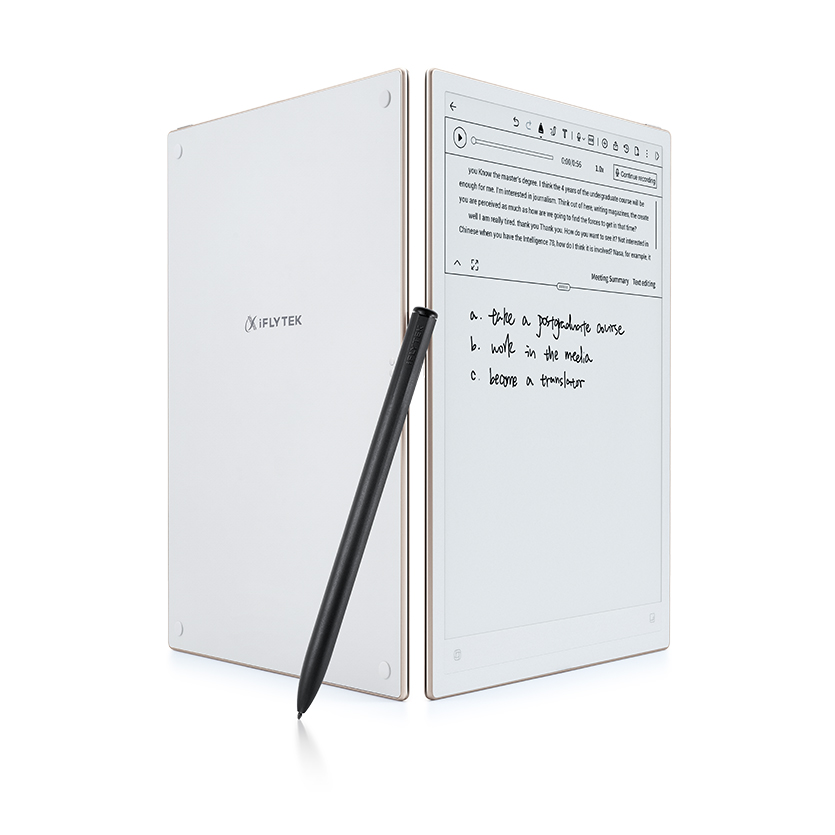

At this year’s World Manufacturing Convention, Spark Trans delivered real-time Chinese–English interpretation, allowing global attendees to follow conference content with ease. During high-level bilateral meetings, the iFLYTEK Translation System—combining the Dual-Screen Translator 2.0 with the Smart Notebook—served as an on-site “super interpreter,” providing reliable support for critical dialogues. Both Spark Trans and the Dual-Screen Translator 2.0 support wireless screen projection. Users can easily connect their tablets via QR code scanning or other simple methods to extend their display, making multilingual interaction smoother and more intuitive than ever before.

At the recently concluded 22nd China-ASEAN Expo, iFLYTEK demonstrated its robust multilingual capabilities. The company unveiled the Spark ASEAN Multilingual Large Model, a foundational AI system specially designed for the ten ASEAN countries. Covering ten languages including Malay, Indonesian, Thai, and Vietnamese, the model delivers performance comparable to top international standards while operating with an order of magnitude fewer parameters — achieving both efficiency and world-class capability.

Teaching Robots to “Learn by Example”: A Key Leap in Advanced Industrial Skills

A highly anticipated frontier in intelligent manufacturing is the rise of embodied intelligence robots. At the convention, iFLYTEK LindenBot showcased its All-in-One Embodied AI Appliance for Data Collection, Training, and Deployment — a setup consisting of an “active arm” and a “passive arm” designed to tackle a fundamental challenge in industrial robotics: the inability of robots to autonomously learn new skills. By simply demonstrating an operation by hand, a worker can have the appliance record the entire process and then "teach" the robot to replicate the action.

The All-in-One Embodied AI Appliance features robust capabilities such as remote control and learning by analogy. It has already been adopted by universities and robotic data training centers, marking its entry into real-world application.

In automotive parts sorting — a scenario involving thousands of components of different specifications — the traditional method requires engineers to manually program each task, leading to high costs and lengthy development cycles. Powered by the iFLYTEK Spark LLM, the All-in-One Embodied AI Appliance for Data Collection, Training, and Deployment overcomes this bottleneck. By fine-tuning the model with only a small amount of real-world operational data, it enables robots to rapidly acquire multiple sorting skills and achieve cost-effective generalization across similar types of tasks. In practice, after just a few rounds of "hands-on training," the robot learns to apply one skill to a variety of tasks — demonstrating true learning by analogy.

Empowering the Entire Value Chain: From Foundational Models to Terminal Applications

Guided by the State Council’s “AI+” initiative, iFLYTEK showcased a comprehensive, end-to-end “AI + Manufacturing” solution at this year’s World Manufacturing Convention, spanning the entire technological chain — from foundational large models to intelligent terminal applications.

On the afternoon of September 21, at the “AI Empowering New Industrialization” Antelope Special Session, iFLYTEK officially launched the Antelope Industrial Large Model 3.0. This release represents a major technological leap, featuring a fully upgraded industrial time-series foundation model capable of “unified representation of time-series signals and unified task modeling.” This breakthrough enables AI systems to process diverse device data—such as temperature, pressure, and vibration—in a standardized manner, eliminating the need for fragmented, scenario-specific customization. During the same session, iFLYTEK introduced three new industrial agents: the Antelope Industrial Agent, the Antelope Energy & Carbon Agent, and the Antelope Digital Marketing Agent. These solutions support manufacturers in key areas including production equipment management, zero-carbon park development, and global marketing, collectively providing an integrated, full-chain intelligent transformation pathway for the industrial sector.

The Spark Automotive Intelligent Agent Development Platform has developed multi-scenario intelligent applications—including a "binge-watching companion" for film and TV entertainment and food recommendations inspired by Xiaohongshu—delivering more precise and personalized experiences for car owners across daily life needs such as dining, travel, and lifestyle services.

Powered by the iFLYTEK Spark LLM, the Spark Automotive Intelligent Agent Development Platform extends advanced AI capabilities directly to the vehicle terminal. The platform has developed multiple scenario-based intelligent applications, including a "binge-watching companion" for film and TV entertainment, NBA game data queries, 24/7 authoritative news aggregation, and Xiaohongshu-style food recommendations. It is reported that the iFLYTEK Spark LLM has been deployed in over 30 mass-produced vehicle models from automakers including Chery, GAC, Great Wall, Changan, Volkswagen, JAC, FAW, and Nissan. To date, iFLYTEK's intelligent automotive solutions have achieved cumulative pre-installations exceeding 65 million units, serving over 27 million active users monthly and handling 16 billion online interactions annually.

The Human Side of Manufacturing: Using AI to Enhance Lives for the Young and Old

Manufacturing produces the goods that sustain our daily lives, cultivates the talent our society needs, and cares for the well-being of every individual — all while serving essential sectors such as education and healthcare.

The iFLYTEK AI Blackboard has now been deployed across 33 provincial-level regions in China, reaching over 1,400 counties and districts and 100,000 classrooms. Virtual teachers such as Zhuge Liang and Einstein interact with students in real time, increasing classroom participation rates to 73%. Meanwhile, the "Qisi Miaowen Curiosity Window" platform features AI mentors modeled on more than ten iconic figures — including Einstein, Li Bai, Lu Ban, and Turing — who now guide over 180,000 primary and secondary school students. These virtual mentors have already inspired more than 3.6 million curiosity-driven questions, encouraging children to explore, imagine, and learn through inquiry.

The on-site "Ear Age Test" experience was a major hit among visitors. The iFLYTEK Smart Behind-the-Ear Hearing Aid Pro, which enables users not only to hear sounds clearly but also to "see" them, has reopened the door to communication for elderly people with hearing loss.

Designed to meet the needs of China's large hearing-impaired population, the iFLYTEK Smart Behind-the-Ear Hearing Aid Pro has achieved cumulative sales of over 140,000 units. As the industry's first device featuring multimodal caption-assisted hearing technology, it converts speech into text in real time, allowing users with hearing loss to both hear and read conversations simultaneously. By literally making sound visible, this innovation is helping China's 120 million elderly individuals with hearing impairment reconnect with society.

More News

-

Industry First: Bluey and Other Classic English Animations Launch Exclusively on iFLYTEK AI Learning Machine

Industry First: Bluey and Other Classic English Animations Launch Exclusively on iFLYTEK AI Learning MachineJanuary 14, 2026

-

iFLYTEK Showcases at the 2025 China International Travel Mart

iFLYTEK Showcases at the 2025 China International Travel MartJanuary 08, 2026

-

2025 World University Presidents Forum Hosts "AI and Scientific Research Paradigms Shift"

2025 World University Presidents Forum Hosts "AI and Scientific Research Paradigms Shift"November 25, 2025

-

iFLYTEK Upgrades Simultaneous Interpretation Model and Launches iFLYTRANS Headsets in Shanghai and Dubai

iFLYTEK Upgrades Simultaneous Interpretation Model and Launches iFLYTRANS Headsets in Shanghai and DubaiOctober 31, 2025

-

Spotlight on DMEXCO 2025: Join iFLYTEK AI Marketing to Shape the AI-Driven Future of Digital Marketing

Spotlight on DMEXCO 2025: Join iFLYTEK AI Marketing to Shape the AI-Driven Future of Digital MarketingOctober 22, 2025